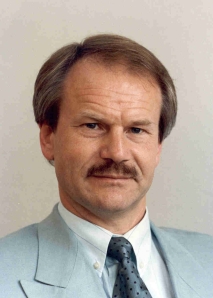

– Prof. Michael Schmidt

PROF. MICHAEL SCHMIDT is the Head of the Institute for Structural Engineering, of the Building Materials Department and Director of the Governmental Testing Institute, University of Kassel. He was previously a Senior Research Engineer at the Research Institute of the German Cement Industry in Düsseldorf. His research areas focuses on the interactions between mineral particle surfaces and organic polar molecules (superplasticisers) on the nanoscale, influence of superplasticisers on rheology of particle suspensions, optimisation of particle size distributions and particle shapes to achieve space filling of interparticular gaps with smaller particles. Development and application of Ultra High Performance Concretes with strengths better than 200 N/mm² and extreme high resistance to environmental and chemical attacks for use in sustainable structures, production and application of earth-moist concretes to improve the manufacturing of precast concrete parts. PROF. MICHAEL SCHMIDT is the Head of the Institute for Structural Engineering, of the Building Materials Department and Director of the Governmental Testing Institute, University of Kassel. He was previously a Senior Research Engineer at the Research Institute of the German Cement Industry in Düsseldorf. His research areas focuses on the interactions between mineral particle surfaces and organic polar molecules (superplasticisers) on the nanoscale, influence of superplasticisers on rheology of particle suspensions, optimisation of particle size distributions and particle shapes to achieve space filling of interparticular gaps with smaller particles. Development and application of Ultra High Performance Concretes with strengths better than 200 N/mm² and extreme high resistance to environmental and chemical attacks for use in sustainable structures, production and application of earth-moist concretes to improve the manufacturing of precast concrete parts.

|

|

ULTRA HIGH PERFORMANCE CONCRETE – RESEARCH AND APPLICATION IN GERMANY AND AROUND THE WORLD

ABSTRACT

Ultra-High Performance concrete is characterized by a practically dense structure, a compressive strength of about 180 to 200 Mpa and thus by a significantly improved resistance to attacks caused by harmful gases and liquids. The fundamental idea was to improve the packing density of the cement matrix and to reduce the water-cement ration to a minimum of about 0.2 – resulting in a ceramic-like concrete structure. Reinforced with steel or other appropriate fibres it behaves sufficiently ductile to design quite filigrane lightweight structures with an outstanding loadbearing capacity and durability. Worldwide activities of some specialised producers of prefabricated dry-mixed UHPC products have already led to numerous prototype applications in Europe, the United States, Asia and Australia. In Germany a 10 Mio. € research program started in 2005 funded by the German Research Foundation and coordinated by the University of Kassel. About 20 Research Institutes are active covering all topics of interest starting from the evaluation of appropriate raw materials including nanotechnological approaches to further improve the performance, the rheological behaviour of the fresh concrete, its mixing and placing, the chemical and mineralogical specifics of the hydration process, the strength and deformation behaviour and – last not least – durability and sustainability aspects. It ends up in material adequate structures and reliable design procedures including new construction technologies like to bond UHPC-elements by gluing. The aim is to make UHPC a commonly available and applicable material for very sustainable, material saving, long lasting and even breathtaking concrete structures or even for applications which are up to now restricted to other materials like ceramics or high performance fibre reinforced plastics. In combination with e.g. nanotechnological developments UHPC can make concrete a multi-purpose “smart material” being able to clean the air from organic and anorganic pollutions.

The paper will present the actual state of research and development as well as different recent applications giving an idea of the high potential of this “material of the millennium”.

|

Leave a comment